The solvent-free, two-component Flow Resin Epoxy Repair Mortar is designed specifically for repairing large cracks and holes in floors and for installing hollow baseboards. Hollow baseboards are widely used in damp areas such as bathrooms, rinse kitchens and slaughterhouses to prevent moisture infiltration. After processing, it is recommended to finish the mortar with an epoxy or polyurethane coating.

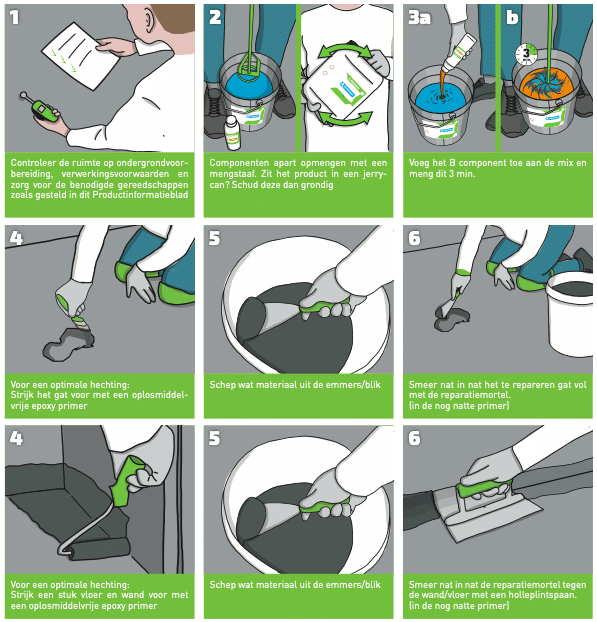

Check the product data sheet and instructions for practical tips and processing instructions.

Applications

Flow Resin Epoxy Repair Mortar is suitable for repairing and forming hollow baseboards, upstands, slopes, sills and thresholds in such applications as:

- Warehouses

- Workshops

- Production areas

- Grand kitchens

- Technical rooms

- Garages

- Parking garages

- Sanitary areas

- Slaughterhouses

- Chemical storage areas

Technical properties

- Impact, shock and abrasion resistant

- Closed surface

- Resistant to chemicals

- Easy processing

- Solvent-free

- Easy to clean

- Good overcoating with PU or epoxy (after primer/scrape coat)

- High mechanical load capacity

Consumption

Consumption depends on the extent and depth of the damage. For hollow baseboards, consumption is approximately 2 kg per running meter at a height of 5 cm. At 1.5 kg per m², a layer thickness of approximately 1 mm is achieved. The exact consumption depends on the shape and height of the skirting board.

Required tools

Required tools include a mixing rod, mixing bucket, trowel or hollow plinth trowel. Use appropriate personal protective equipment such as safety glasses, protective clothing and gloves. Clean tools with Flow Resin Tool Cleaner.

Preparation of the substrate

Ensure the substrate is dry and dust-free. Apply the repair mortar to a previously applied Flow Resin Epoxy Primer within the specified application time. If this fails, it is usually not a problem with this product.

Additional Information

For technical tips, step-by-step instructions and comprehensive product information, refer to the product data sheet and instruction manual.

Reviews

There are no reviews yet.