The two-component Flow Resin Epoxy Primer for Moist Subfloors is specially designed for subfloors with excessive moisture content. This epoxy primer provides excellent adhesion to damp substrates and serves as a base coat for all Flow Resin systems or other floor finishes. Suitable for indoor use only.

Check the product data sheet and instruction manual for tips and instructions on applying floor coatings.

Applications

- Suitable for concrete, cement screeds, smoothing compounds and contaminated floors with up to 10% moisture

- Ideal as a base coat on damp substrates for any floor finish

- Adhesive primer for Flow Resin Epoxy Repair Mortar, Leveling Epoxy, Epoxy Scraper Coat and Epoxy Floor Coating PRO

- Submitted primer for increased peak loads in industrial casting floors

Technical properties

- Moisture barrier for substrates with 4-10% residual moisture

- Glossy, seamless and liquid-proof surface

- Strengthens the substrate and is solvent-free

- Good venting and easy to process

Consumption

Depending on substrate structure: 400-500 g/m² on even substrates, 450-600 g/m² on uneven substrates. Apply an opaque coat for optimum moisture protection.

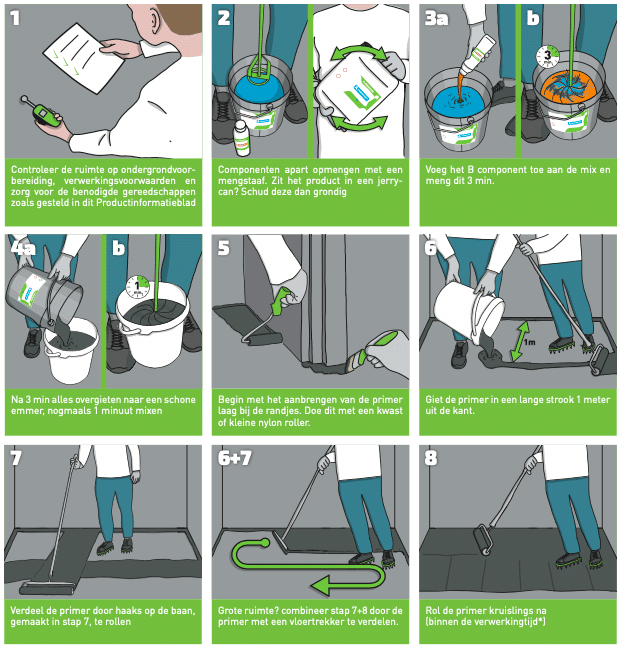

Required tools

Brush, nylon roller with bracket and telescopic handle, gloves, mixing rod, mixing bucket, safety glasses. For larger areas: floor squeegee and cross roll. Use tape for tight edges.

Preparation of substrate

Make sure the substrate is dry and dust-free. Remove cement and concrete residue by sanding or grinding. Rough concrete should be blasted or coarsely sanded. Chemically clean and sand when contaminated. Treat oil stains with cat grit or ammonia. Vacuum thoroughly. Repair small blemishes with Flow Resin Epoxy Putty, larger ones with Flow Resin Epoxy Repair Mortar. Finish edges with acrylic sealant and tape.

Application on tiles or ceramics

Open up the tile floor with a bowl wheel on an angle grinder. Degrease and make dust-free. Then apply the primer. For an even finish: level with Flow Resin Epoxy Equalizer.

Anti-slip and peak load increase

For heavily loaded floors: mix 10% Flow Resin Heavy Duty Antiskid into the primer or sprinkle 750 g/m² into the wet coat. This increases grip and peak load. Vacuum before applying the next coat.

Tips and instructions

Read the product data sheet and instructions for use carefully for technical tips and processing instructions.

Reviews

There are no reviews yet.