Application

- Sealer

- Topsealer

- Sealer and infill layer for DIBt-approved systems for accommodation spaces (AbZ Z-156.605-1414; Z-156.605-1487)

Features

- Silk gloss finish

- Equipped with anti-slip

- Vapor permeable

- Free of plasticizers, nonyl and alkyl phenols

- Physiologically harmless when cured

Processing

Processing temperature (material, environment and substrate): minimum +8°C and maximum +30°C. Protect the applied material from moisture during curing to prevent surface differences and reduced adhesion. Relative humidity should not exceed 80%. The substrate temperature during application and curing must be at least +3°C above the dew point. Ensure adequate air circulation to allow moisture to evaporate. If necessary, divide the surface into smaller sections.

Subsurface requirements

The substrate must be stable, load-bearing, clean and free of loose particles, dust, oil, grease, rubber traces and other adhesion-inhibiting substances. Pretreatment with suitable Remmers WDD products is required.

For detailed product and safety information on Epoxy BS 3000 SG, see the “Downloads” tab above.

Handy manual

Download the floor coating installation manual for a step-by-step explanation of how to apply floor coating. You will also receive this manual by email after your order. More tips and inspiration? Check out our YouTube page of instructional videos.

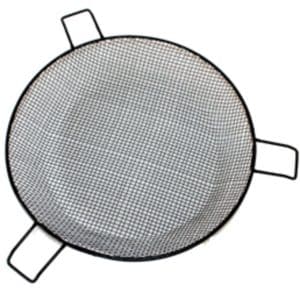

No tools at hand?

Easily assemble your tool kit for any type of floor.

Substrate

An even and stable subfloor is essential for a tight end result. For repairs, use Epoxy repair mortar and/or Epoxy putty. To level the floor, use Epoxy Scraping Layer HQ. For leveling, go to Equalization.

Free* RAL range

Order the RAL color chart and choose the right color for your project.

Reviews

There are no reviews yet.