Arturo EP1200 Trowel Flooring is a durable, seamless finish for cement and gypsum-based substrates and tile floors.

Applications:

- Industrial Halls

- Slaughterhouses

- Grand kitchens

- Workshops

Ideal for areas with high demands for mechanical and chemical stress and hygiene.

Features

- High compressive strength

- Impact, shock and abrasion resistant

- Suitable for baseboard finishing

- Processable with hand tools or butterfly machine

- Component C is colored

- Suitable for slope processing

- Also applicable to baseboards and upstands

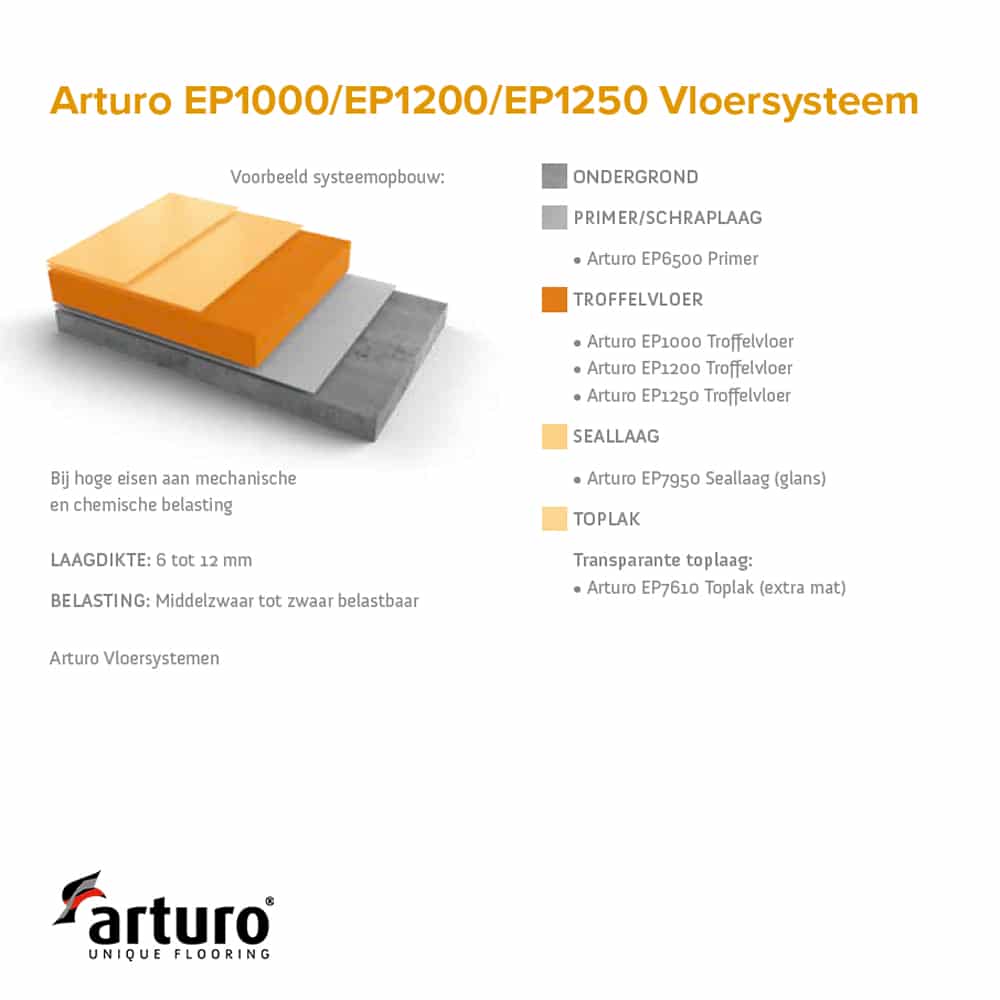

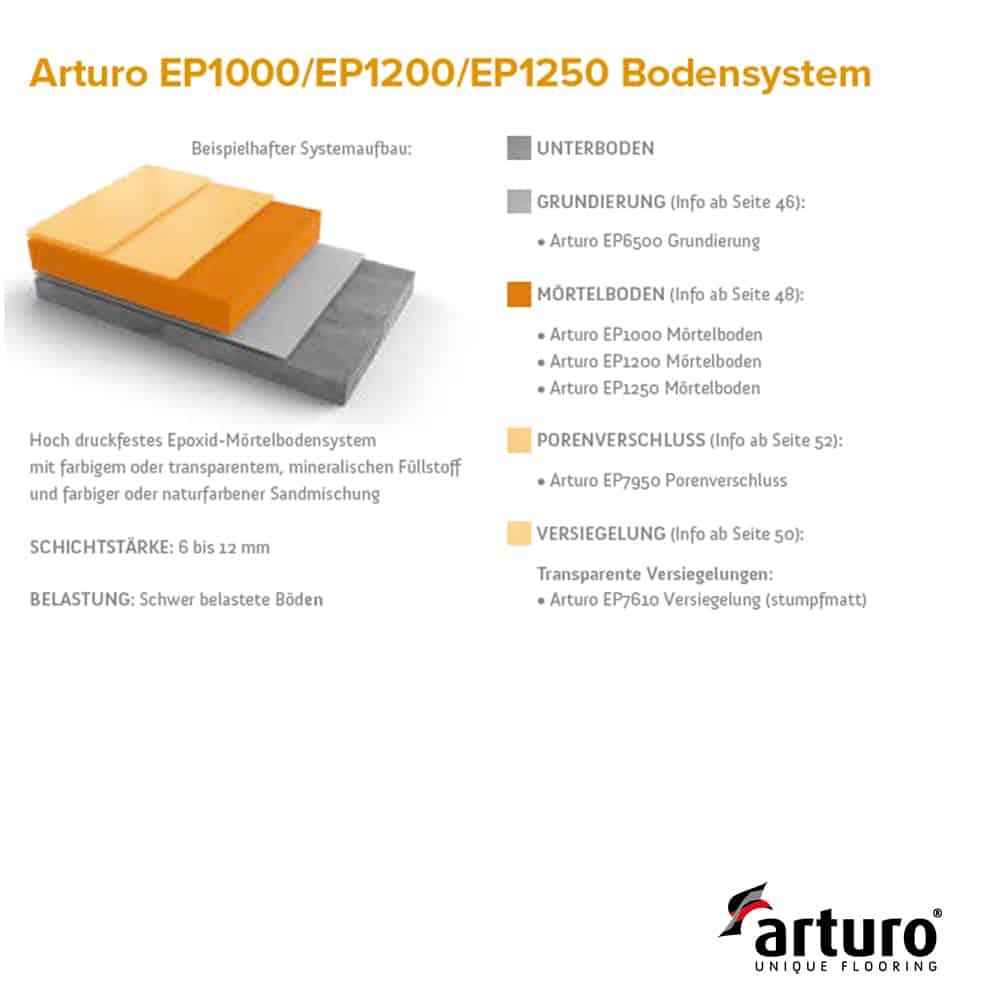

System Structure

Primer/Scraper coat:

- Use Arturo EP6500 Primer* and/or Arturo EP6200 Scraping Layer* for cement and gypsum-based substrates.

Trowel floor:

- Arturo EP1200 Trowel Flooring

Top Coat/Seal Coat/Anti-slip:

- For a liquid-tight, matte finish: first apply Arturo EP7950 Seallcoat*, then finish with Arturo PU7750*, PU7320* or EP7610* Topcoat.

- For anti-slip: add anti-slip grit to the above top coats.

Consumption

Consumption: 1.5 kg per mm layer thickness per m². Recommended layer thickness: 5-12 mm (7.5-18 kg/m²). One set contains 74.25 kg.

Underground requirements and preparation

Remove cement skin and concrete residue by sanding or grinding. Roughen smooth substrates (such as concrete) with dust-free ball blasting. Blast or sand anhydrite floors. Chemically clean contaminants and then sand. Always dust with an industrial vacuum cleaner. Fill cuts and holes with suitable filler. Repair cracks with Arturo EP1500 Repair Mortar*.

See the product data sheet for specific substrate requirements.

More information?

View detailed product, application and safety information under the ‘Product Attachments’ tab.

Reviews

There are no reviews yet.