The Flow Resin Epoxy Primer for Cement screeds is a solvent-free, water-based two-component primer with excellent adhesion. Specially designed for cement screeds and other porous substrates, this primer forms a strong, vapor-permeable layer. This makes it suitable for indoor and outdoor applications, such as balconies and galleries, in combination with the Flow Resin Epoxy Floor Coating ECO Waterborne. Its vapor-open properties allow residual moisture to escape from the substrate when combined with a waterborne coating. The primer is also compatible with other Flow Resin floor coatings and screeds, provided the residual moisture content is below 4%.

Applications

- Sand-cement screeds

- Equalin

- Fresh cement screeds (vapor permeable primer)

- Balconies and galleries (vapor permeable system, 4-10% moisture)

- Adhesive primer for Equalize Epoxy or Epoxy Scrape Coat (<4% moisture)

- Adhesive primer for Epoxy Floor Coating PRO (<4% moisture, possibly sanded in with Heavy Duty Antiskid)

- Submitted adhesive primer for EP Cast Flooring Industry

- Vapor-open adhesive primer for indoor areas (all Flow Resin coatings at <4% moisture, ECO Waterborne up to 10%)

- Adhesive primer for adhesives (PVC, textile, laminate, rubber)

Technical properties

- Glossy appearance

- Waterborne

- Seamless

- Easy processing

- Anticrater additive

- Good venting

- Increase wear resistance with sand

- Solvent-free

- Easy to clean

- Good coverage

- Mechanically loadable

Consumption

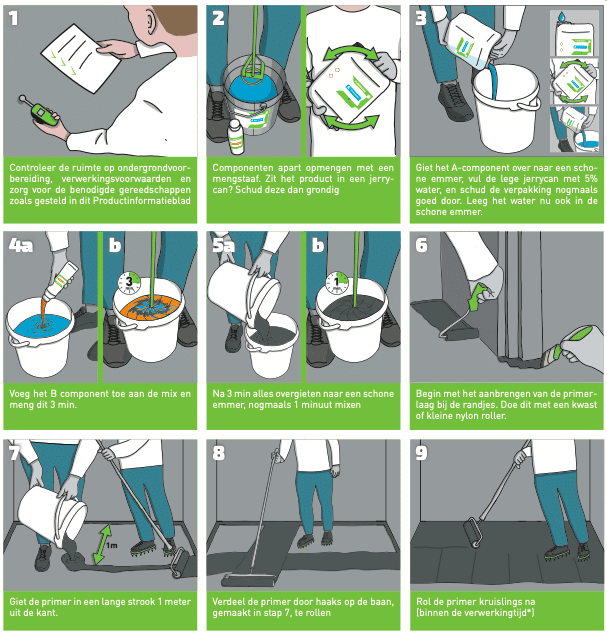

Depending on the substrate: 150-200 g/m² for smooth, moderately absorbent substrates; 200-250 g/m² for rough, highly absorbent substrates. Consumption may be higher in the case of many small holes.

Adding water

The primer is water-based and should be diluted with 5-10% water (of the total weight of component A + B).

- 5% water: better rollability, higher filling capacity, shorter processing time

- 10% water: deeper penetration, better adhesion, less solids per m² (note pinholes)

Required tools

- Brush (edges)

- Nylon roller + bracket (possibly telescopic handle)

- Mixing bucket + mixing rod

- Gloves, safety glasses

- Floor squeegee (for large areas)

- Tape (for tight edges)

- Tool Cleaner, cloths

Substrate preparation

The substrate must be dry, clean and dust-free. Remove cement residue by sanding or grinding. Roughen rough or dense substrates. Chemically clean and sand contaminants. Treat oil stains with cat litter or ammonia. Repair small blemishes with Epoxy Putty, larger ones with Epoxy Repair Mortar. At 4-15% moisture: use Primer Moist Substrates. At <10% moisture: use this primer only with ECO Waterborne coating. Below 4%: suitable for all Flow Resin systems.

Application on balcony or gallery

Apply only to dry, clean substrates. Do not use Primer Moist Substrates on wet substrates. Choose a dry day for application.

Anti-slip and peak load increase

For heavy-duty floors: mix 10% Heavy Duty Antislip into the primer.

Reviews

There are no reviews yet.