Application

Wilsor polyester resin is a synthetic resin that cures after the addition of a hardener. It is used for making yachts, spoilers and sculptures, among other things. The strength of polyester resin is obtained by using reinforcement materials such as glass mat, kevlar or carbon. The resin is applicable to substrates such as stone, steel, polyester and epoxy, provided they are grease-free and roughly sanded. Polyester resin does not adhere to epoxy, polyethylene and Teflon.

Reinforcement material

Because polyester resin is inherently brittle, it must be reinforced with a reinforcement material such as fiberglass, carbon or kevlar mat. These are available as woven mat or shredded mat.

Polyester resin versus Epoxy resin

Advantages

- Fast curing

- Affordable price

- Cure adjustable by amount of hardener

Cons

- Shrinkage, which can lead to reduced adhesion

- Characteristic odor

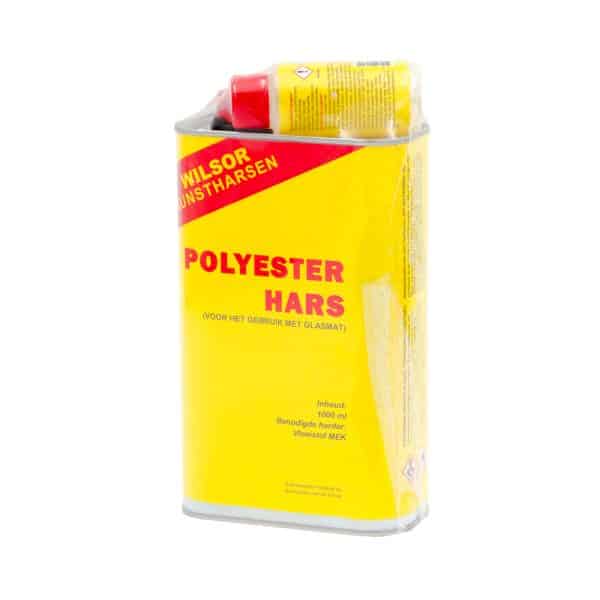

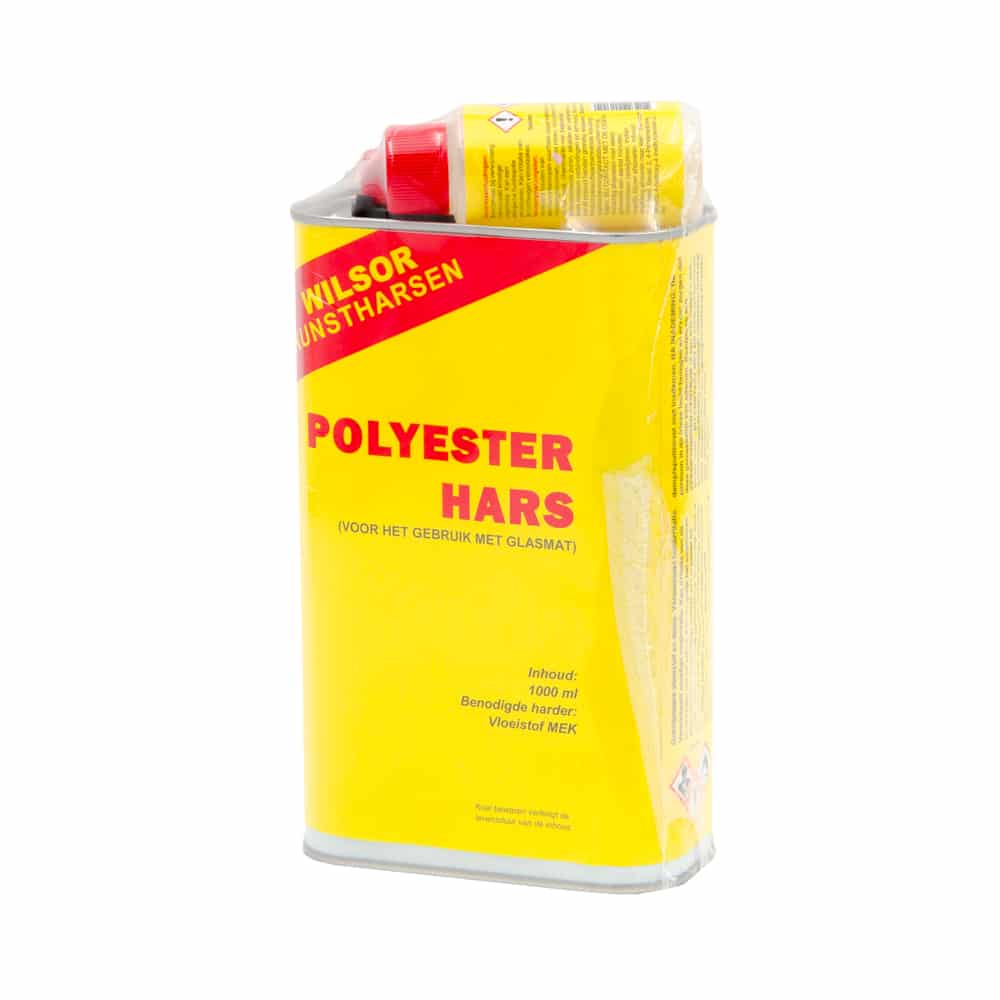

Packaging

- 250 ml + 20 g BP hardener (tube)

- 500 ml + 30 g BP hardener (tube)

- 1 liter + 40 ml MEK hardener (bottle) – this product

- 5 liters + 200 ml MEK hardener (bottle)

- Repair kit Wilsor

User Manual

- Sand the damaged surface and make sure it is dry, dust- and grease-free.

- Add hardener: approx. 2% to max. 4% of the resin volume. More hardener speeds up the curing process. The 250 ml and 500 ml containers use a BP hardener in paste form, which should be rubbed well against the wall of the mixing cup for proper mixing. The 1 liter and 5 liter containers use a MEK hardener in liquid form.

- Apply the resin with a brush and place the reinforcement material in the wet resin.

- Press the reinforcement material firmly so that it is completely soaked with resin. Avoid air bubbles.

- After curing, protruding fibers can be cut away and the surface sanded and finished with a coating.

Reviews

There are no reviews yet.