The Flow Resin PU Casting Floor Commercial is a glossy, two-component casting floor based on solvent-free polyurethane resin. Available in color, this floor offers a luxurious look with high walking comfort. Due to its elastic properties, the floor feels softer than a hard coating. Compared to the Flow Resin PU Casting Floor Residential, this product is more economical, partly because of its lower UV resistance. This is easily solved with the Flow Resin PU Colored Topcoat. Ideal for commercial spaces, schools and work environments where comfort and appearance are important.

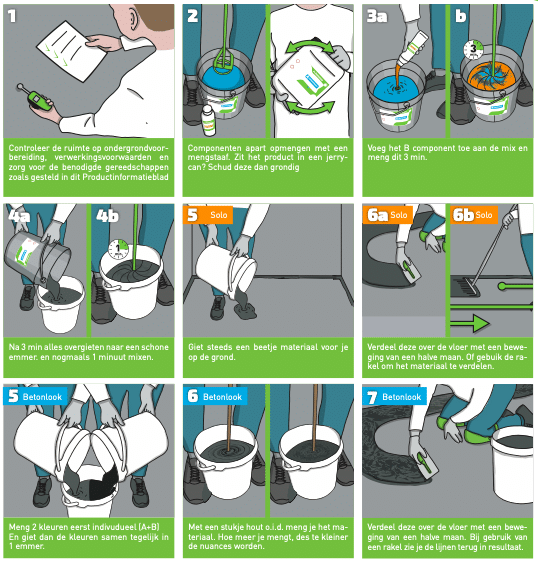

Check the product data sheet and instructions for application tips and instructions.

Applications

Suitable for comfortable, colored floor finishes in such areas as:

- Offices

- Showrooms

- Hospitality

- Housing

- Schools

- Canteens

- Health Centers

- Technical rooms

- Wet areas

- Floors with underfloor heating

Technical properties

- Glossy appearance, matte finish with colored topcoat

- Seamless and liquid-proof

- Easy to apply

- Wear-resistant

- Solvent-free

- Elastic

- Good coverage

- Less UV-resistant than the residential version

Consumption

Recommended consumption: 2.5 to 3 kg/m².

Special effects

For lines, use fineline tape and colored top lacquer. Anti-slip is achieved by adding PU anti-slip beads to the colored or transparent top lacquer. For a striking effect, color flakes can be added to the transparent top lacquer. A concrete look is created by partially mixing two colors of screed.

Increase scratch resistance

Use a clear top lacquer for extra scratch resistance and a matte finish. For UV protection and scratch resistance, choose the colored top lacquer.

Cast floor in the bathroom

In bathrooms, a hollow plinth can be made with epoxy repair mortar to prevent water infiltration. An I-Drain allows the floor to flow seamlessly into the drain channel.

Preparation of substrate

A level surface is essential for a tight result. First apply an appropriate epoxy primer followed by an epoxy scraper coat. The screed should be applied within 16 to 36 hours of the scraper coat. If the scraper coat has already cured, it must be sanded and cleaned.

Instructions and tips

Read the product data sheet and instruction manual carefully for technical tips and a step-by-step guide.

Note: As of Aug. 24, 2023, appropriate training is required for industrial or professional use.

Reviews

There are no reviews yet.