The two-component, solvent-free Flow Resin Epoxy Scraper Coat is specially designed for leveling uneven substrates and filling height differences. Thanks to its lightly filled composition, small cracks and holes can be directly included in the leveling layer. The low viscosity makes the product easy to apply with a trowel or squeegee. Alternatively, there is the Flow Resin Equalizing Epoxy, which flows like a leveler.

Also check out the product data sheet and instruction manual for tips and instructions on how to apply a floor coating.

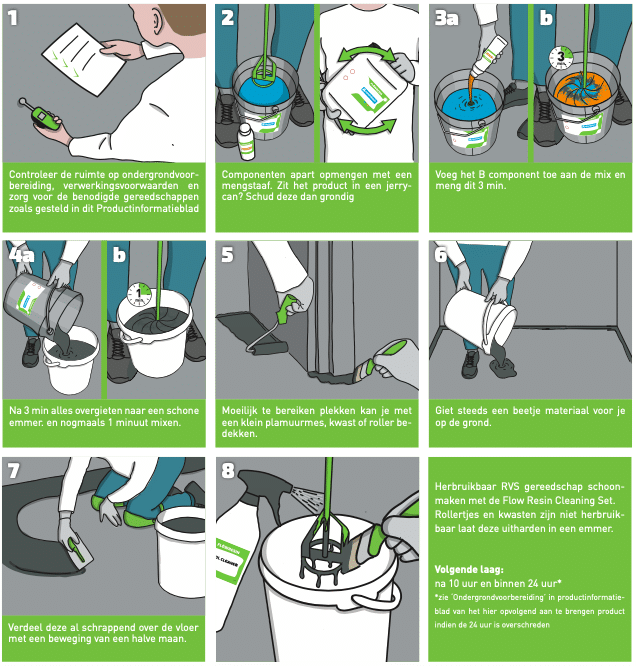

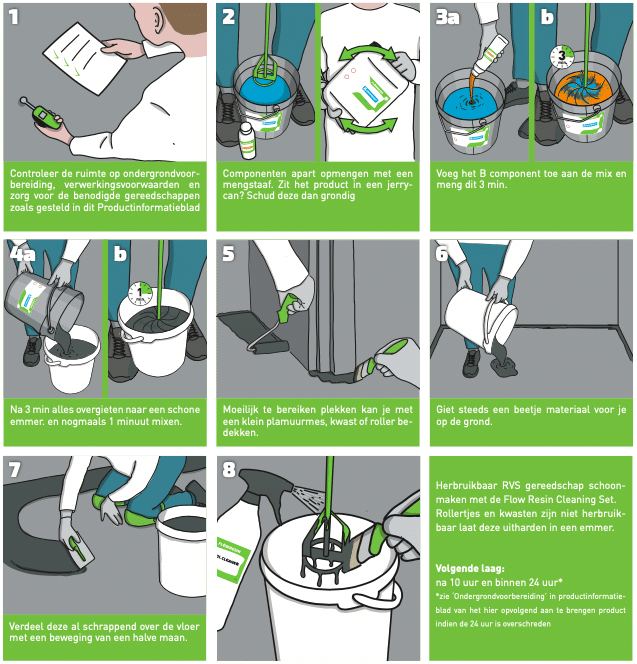

Application

- As a levelling layer under a Flow Resin PU Cast Floor Commercial, Flow Resin PU Cast Floor Residential, Flow Resin EP Cast Floor Industrial or Flow Resin Epoxy Floor Coating PRO

- For leveling raw concrete floors (after primer)

- For leveling out tile floors after using Flow Resin Epoxy Primer for Tile Floors

- As a scraper layer under epoxy floor coating for a smooth result; optional sanding for extra adhesion and anti-slip

(Technical) Features

- Low viscosity, glossy appearance

- Seamless and liquid-proof

- Easy to apply

- Contains anticrater additive

- Good venting

- Solvent-free

- Mechanically strong and high hardness

- Excellent foundation for a cast floor

- Can be sanded in for better adhesion of the next coat

Consumption

Consumption depends on the flatness of the substrate and the desired elevation. For slight irregularities, consumption is approximately 1.5 kg/m² (1 mm). For larger irregularities, this increases to 3 kg/m² (2 mm) or a maximum of 4.5 kg/m² (3 mm). A second coat may be required for a completely flat substrate under a thin floor coating. An alternative is to apply the floor coating thicker with a floor squeegee and roll after. The Flow Resin PU Casting Floor Residential, Commercial and EP Casting Floor Industrial are applied thickly as standard, eliminating minor unevenness.

Tools

Equipment needed: mixing rod, mixing bucket, flat trowel/tooth trowel or squeegee (1.4 mm), telescopic handle, gloves, protective clothing and safety glasses. For larger areas, squeegee and spike shoes are recommended. Due to good venting, re-rolling with a vent roller is not necessary.

Substrate preparation

The substrate must be dry and dust-free. Apply the scraper coat to a fresh Flow Resin Epoxy Primer within the specified application time. Once the primer has cured, the floor should be sanded and cleaned. Large holes and cracks should be repaired with Flow Resin Epoxy Repair Mortar, smaller ones with Flow Resin Epoxy Putty.

Tips and instructions

For technical tips, step-by-step instructions and comprehensive product information, refer to the product data sheet and instruction manual.

Reviews

There are no reviews yet.